Ho hum - another Sunday morning, another Fife paper mill

Smith Anderson & Co had been making paper at it's Fettykill (or perhaps Fettykil) mill since 1859. From the start, the company specialised in paper bags and packaging - Charles Anderson himself invented an automated paper bag making machine.

In 2006, the papermaking business went into receivership - the parent company still makes packaging, but they don't make thier own paper any more, so the Fettykill mill stands empty. It had been the only Scottish mill which used purely recycled paper - no virgin pulp.

To start with, I was a bit worried that things had been all stripped out.

There were some lovely old stone buildings, but all in a state of decay.

Going further into the maze of interconnected buildings, there's some more signs of modern machinery.

Then, turning a corner, bingo

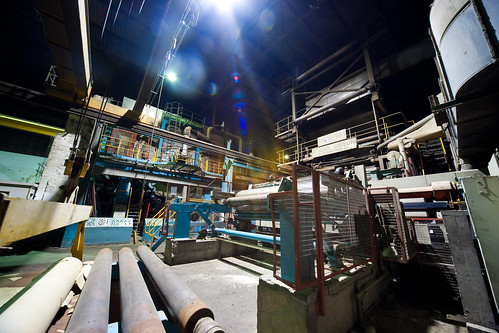

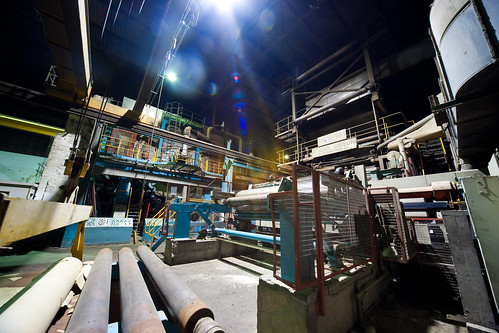

Two absolutely gigantic yankee dryer Fourndrinier paper machines. A yankee dryer machine uses one giant steam-heated roller to dry the paper instead of a series of small rollers.

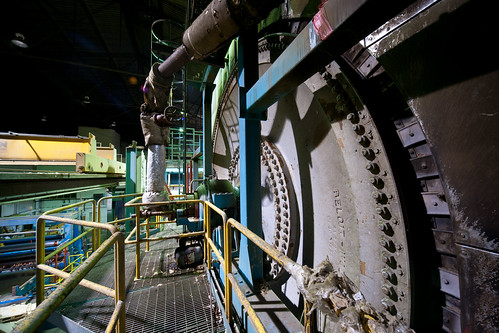

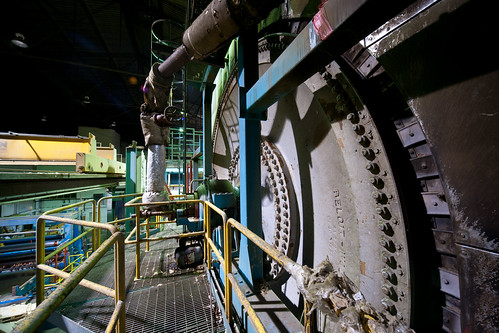

A closer look at a yankee dryer. This roller weighs 80-100 tons, and must be 20 feet in diameter. Apparently if they ever stop moving the bearings are destroyed, so these ones will need new bearings.

Climbing right up to the top of one machine, you can look down onto the two Fourndrinier tables - the mesh has been removed.

Looking the other way at the yankee dryer, you can see the big steam box that encloses it.

Back down to the floor, for a look at the whole machine. I really liked this mill because the machines were in a big shed - you could see all of them at once. Other mills I've visited have the machines in very cramped sheds so it's hard to get an overall view like this.

Along a bit to look at the table where mesh would have carried the pulp in the first stage.

Onwards, and a wee stop-off in a samples store:

A packaging section.

And an external view.

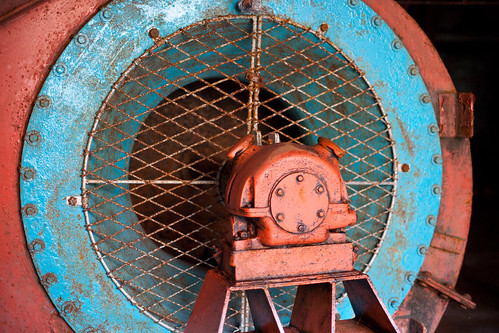

Next, and a rather convoluted way of getting into the old power plant. This is the top of the boilers, with the end of the conveyor that carried coal to the furnaces.

A little bit further down, and a live control panel - though the power plant is no longer used, the substations are still live, running lighting and pumps.

Down to the bottom floor, and some lovely old boilers.

And a brilliant old control panel - with a Hopkinson gauge.

Finally, a view along all three boilers.

Loads more pictures, as usual, are in my FLickr set...

Smith Anderson & Co had been making paper at it's Fettykill (or perhaps Fettykil) mill since 1859. From the start, the company specialised in paper bags and packaging - Charles Anderson himself invented an automated paper bag making machine.

In 2006, the papermaking business went into receivership - the parent company still makes packaging, but they don't make thier own paper any more, so the Fettykill mill stands empty. It had been the only Scottish mill which used purely recycled paper - no virgin pulp.

To start with, I was a bit worried that things had been all stripped out.

There were some lovely old stone buildings, but all in a state of decay.

Going further into the maze of interconnected buildings, there's some more signs of modern machinery.

Then, turning a corner, bingo

Two absolutely gigantic yankee dryer Fourndrinier paper machines. A yankee dryer machine uses one giant steam-heated roller to dry the paper instead of a series of small rollers.

A closer look at a yankee dryer. This roller weighs 80-100 tons, and must be 20 feet in diameter. Apparently if they ever stop moving the bearings are destroyed, so these ones will need new bearings.

Climbing right up to the top of one machine, you can look down onto the two Fourndrinier tables - the mesh has been removed.

Looking the other way at the yankee dryer, you can see the big steam box that encloses it.

Back down to the floor, for a look at the whole machine. I really liked this mill because the machines were in a big shed - you could see all of them at once. Other mills I've visited have the machines in very cramped sheds so it's hard to get an overall view like this.

Along a bit to look at the table where mesh would have carried the pulp in the first stage.

Onwards, and a wee stop-off in a samples store:

A packaging section.

And an external view.

Next, and a rather convoluted way of getting into the old power plant. This is the top of the boilers, with the end of the conveyor that carried coal to the furnaces.

A little bit further down, and a live control panel - though the power plant is no longer used, the substations are still live, running lighting and pumps.

Down to the bottom floor, and some lovely old boilers.

And a brilliant old control panel - with a Hopkinson gauge.

Finally, a view along all three boilers.

Loads more pictures, as usual, are in my FLickr set...