- Joined

- Jan 6, 2013

- Messages

- 5,574

- Reaction score

- 11,213

1. The History

Ceulan Woollen Mill is located in the village of Tal-y-bont in Ceredigion, located halfway between Aberystwyth and Machynlleth. The village stands on two rivers, the Afon Ceulan and Afon Leri. These fast-flowing rivers attracted a number of mills to the village. Three were built along the Leri while a single mill was built on the Afon Ceulan. It was built in 1847 by the Morris family and was working by 1860. It produced cloth and flannel mainly for shirts for farmers and coal miners throughout mid and south Wales. The building consisted of two storeys and an attic and was constructed of split local rubble in a lime mortar, under a slate roof. Due to the success of the mill, it was extended in 1880 and a 7.7m diameter breast-shot waterwheel added against the mill’s southwest gable.

The waterwheel powered the mill machinery and in around 1920 it also drove an electric generator. In 1923 a double Pelton wheel turbine was installed by Edwards of Llanuwchllyn, on the north-east gable in order to drive both the mill machinery and an electric generator. During the Second World War, production and profits suffered. Thinks improved post-1945 but the mill struggled to complete with the bigger mills and their large modern machinery. It struggled on for around a decade before the mill ceased working around 1955, despite turning part of the mill into a shop to sell the directly to the public. It was then eventually abandoned in 1962. Sometime after the owner attempted to pass the mill to the National Trust for preservation. A lack of funding to restore and repair the mill meant the NT were unable to take the mill on.

2. The Explore

So the main reason for driving the 15 of so miles south of where we were staying to Tal-y-bont was to see Leri mill with is colourful yarns. This proved too much of a challenge sadly. The mill lies over the River Leri, reached either across the fallen tree over the river or via a wade. With the biblical rainfall the day before the river was swollen and fast flowing so neither option appealed. I even tried approach from the west but the mill lies at the bottom of a steep bank. So plan B was to check out Ceulan Mill. Entry was pretty straight forward and the main challenge was how to best capture this packed-to-the-gills three storey mill in extremely poor light. Hopefully I just about managed that. After a good hour or so it was time to head back to the car and back up to Mach.

3. The Pictures

All phone pics, using a combination of natural light and my torches.

And we’re in:

It’s pretty overwhelming:

The amount of machinery on the ground floor is ridiculous:

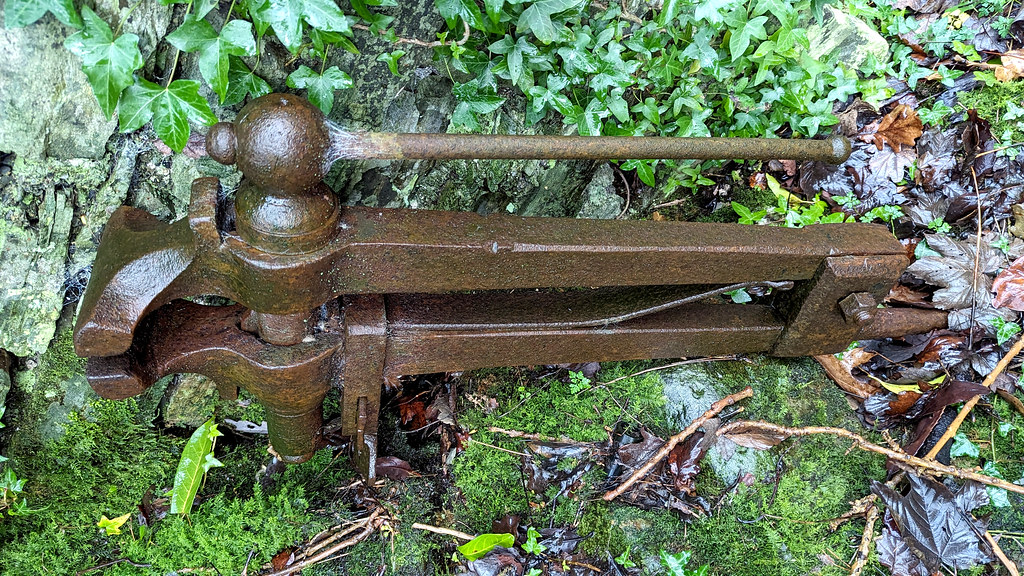

Not too sure what these are:

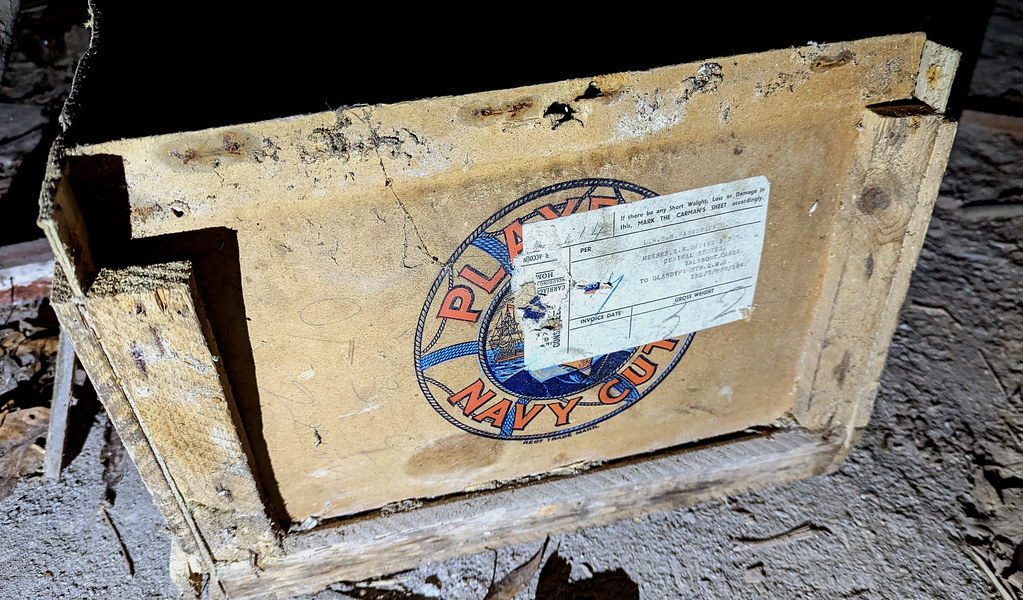

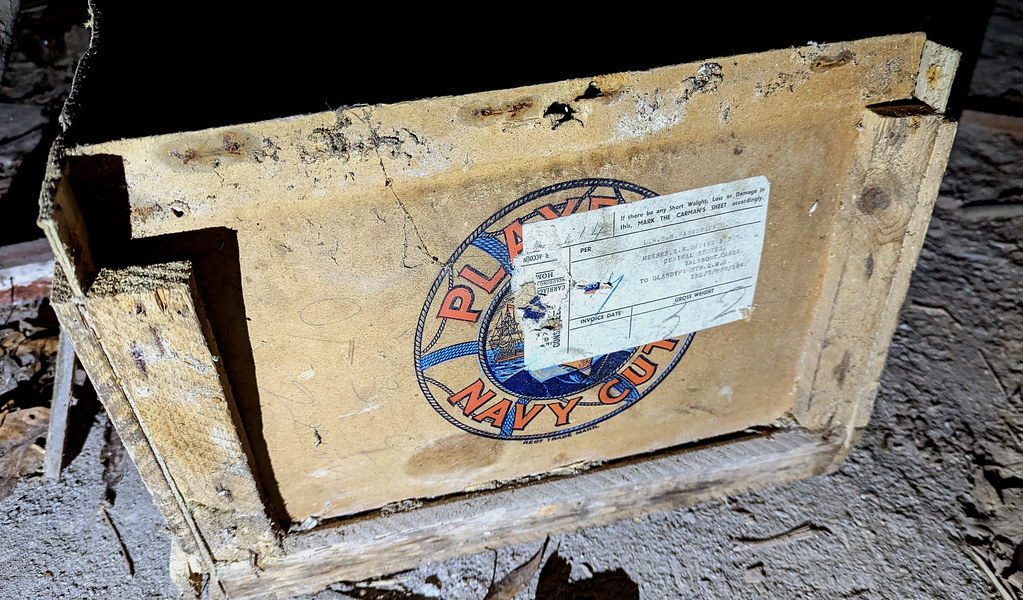

Cool old Player’s box:

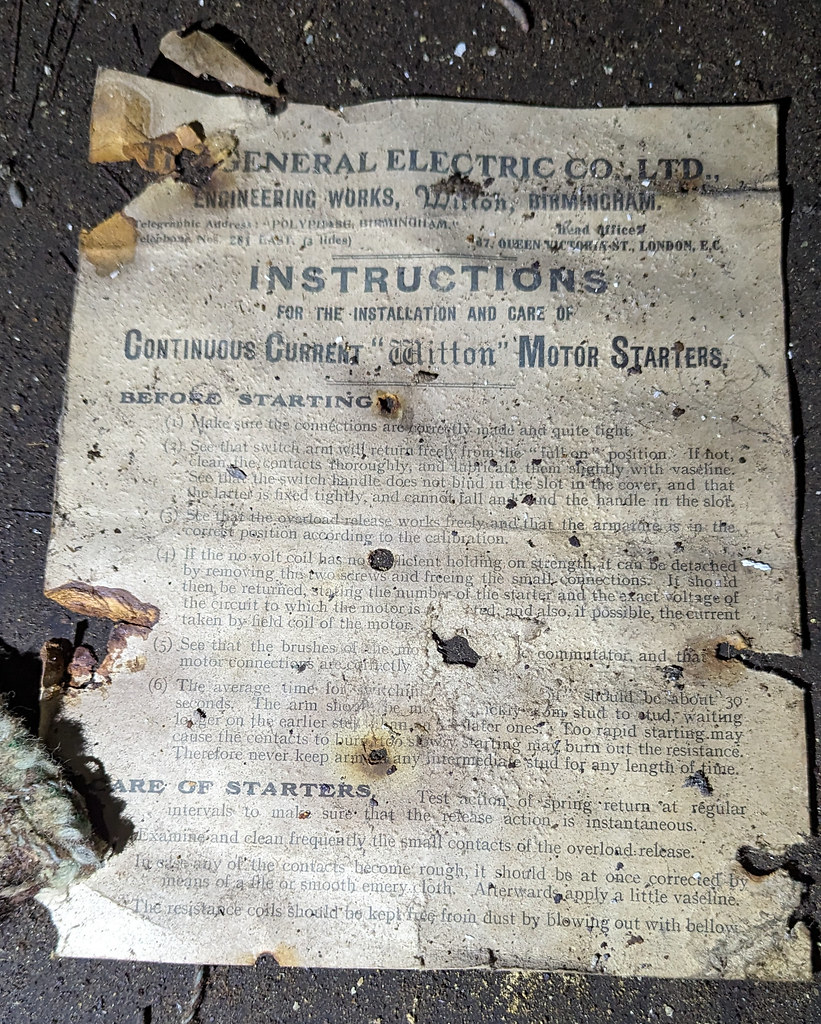

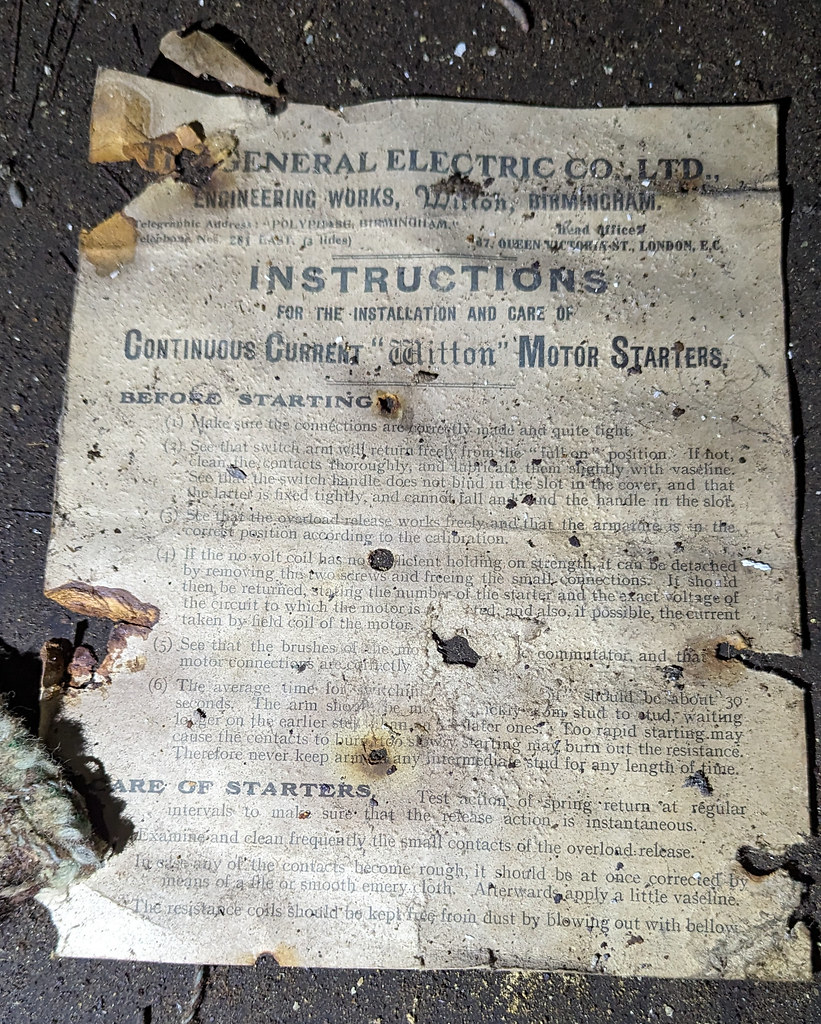

Some old documentation:

And very old electrics:

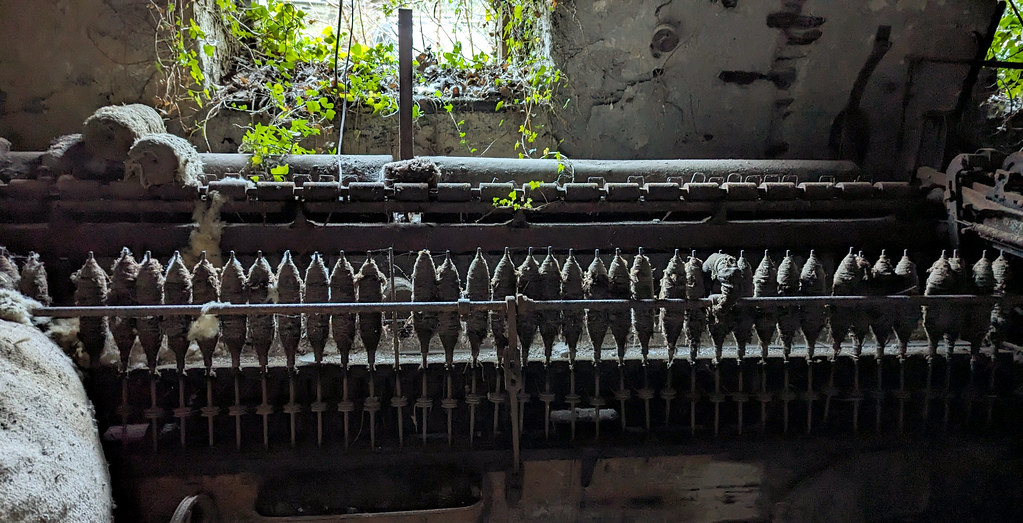

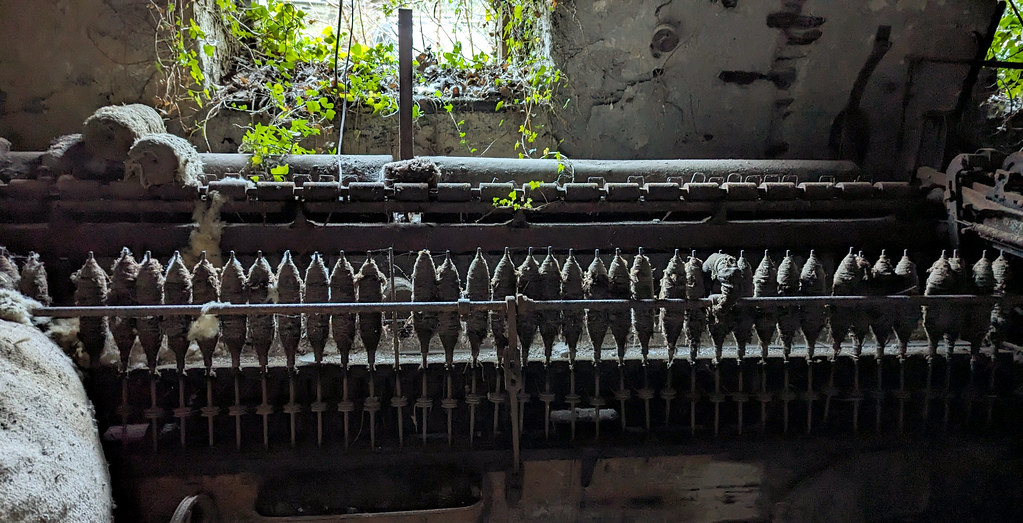

What a load of old bobbins:

These cog wheels are fantastic:

There’s even an old butter churn:

More bobbins!

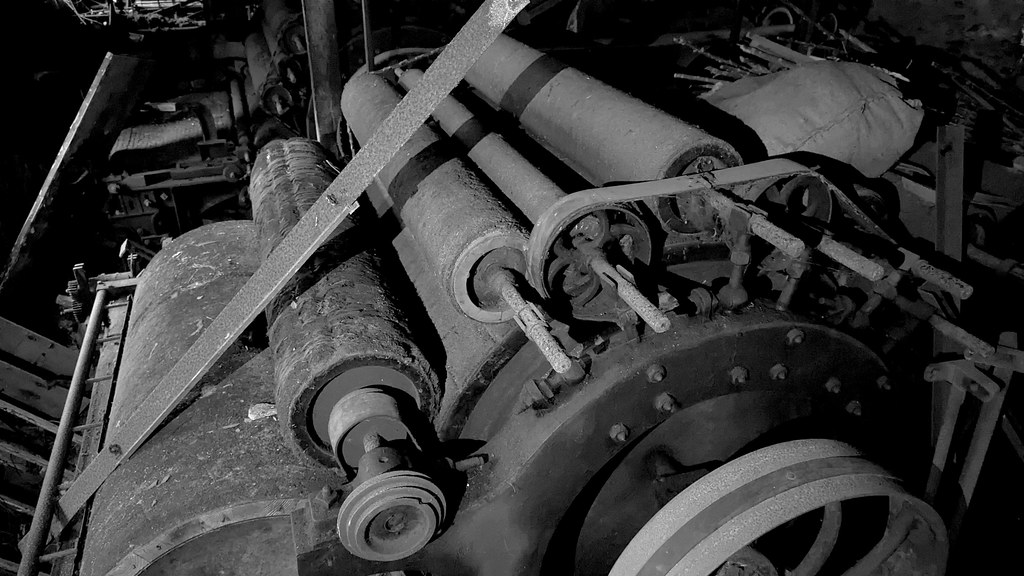

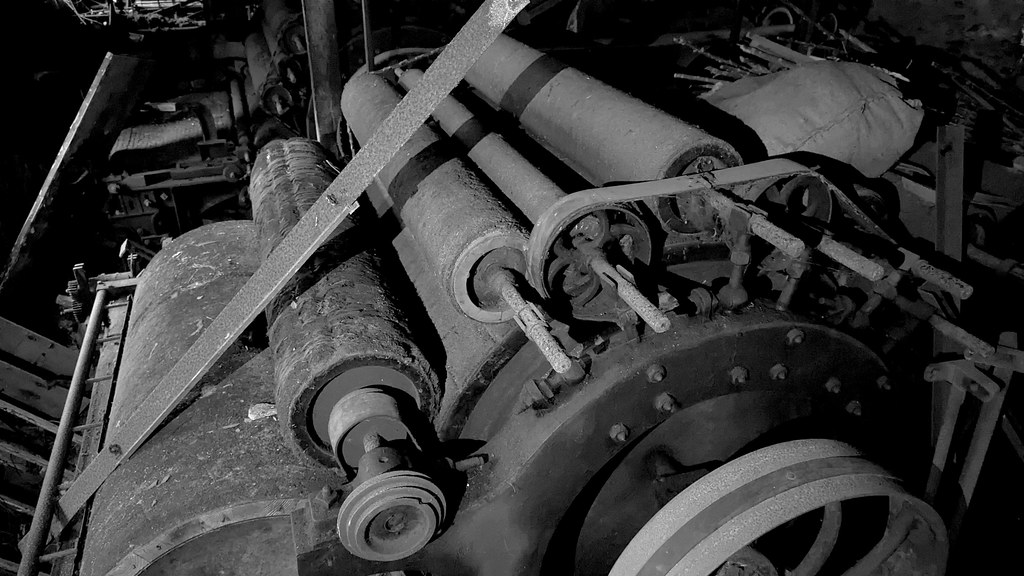

In black and white:

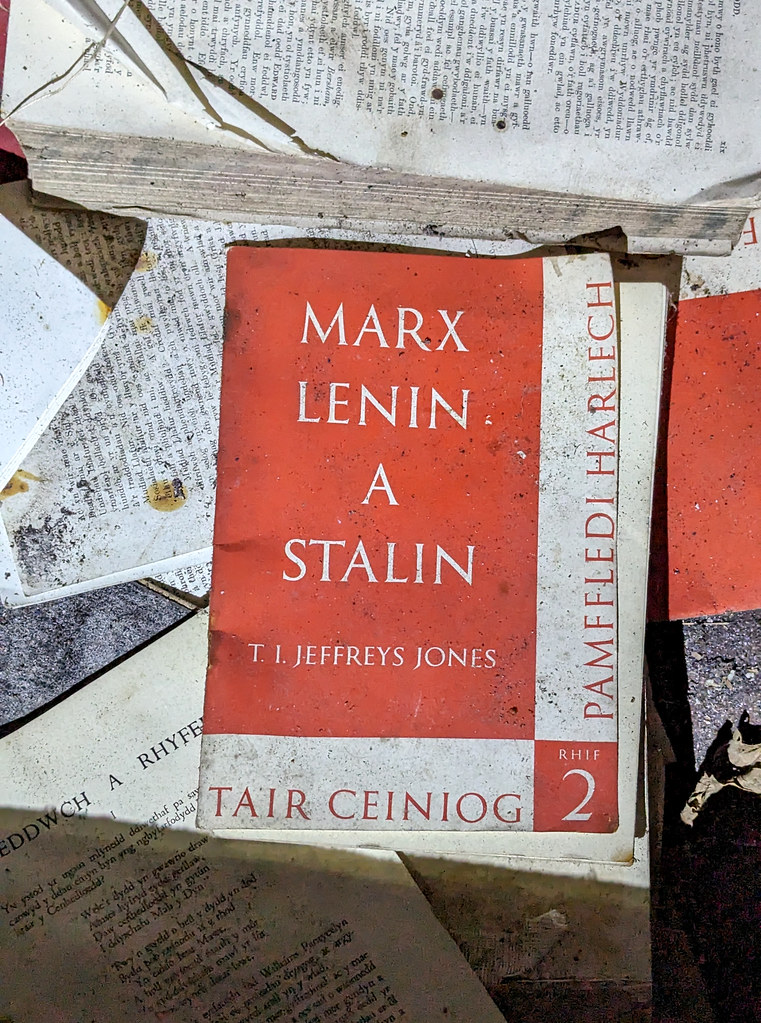

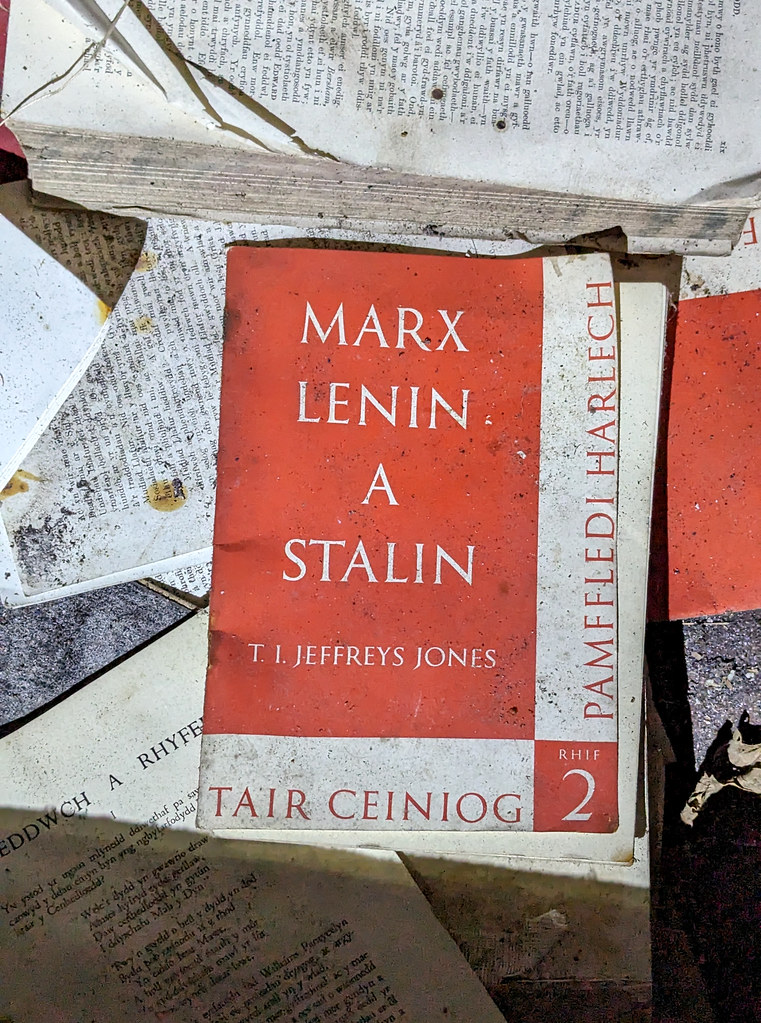

One for the comrades!

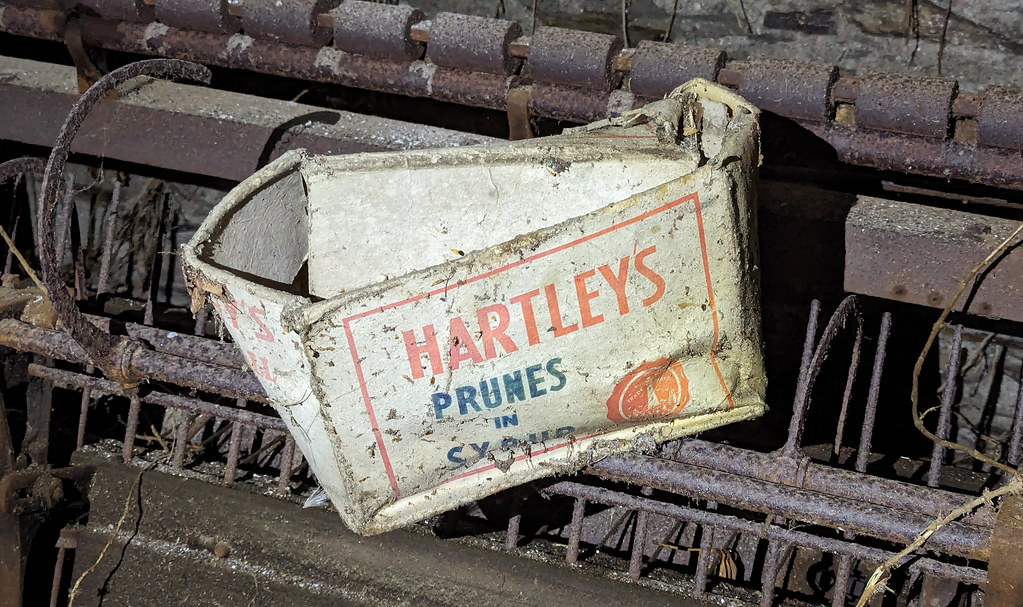

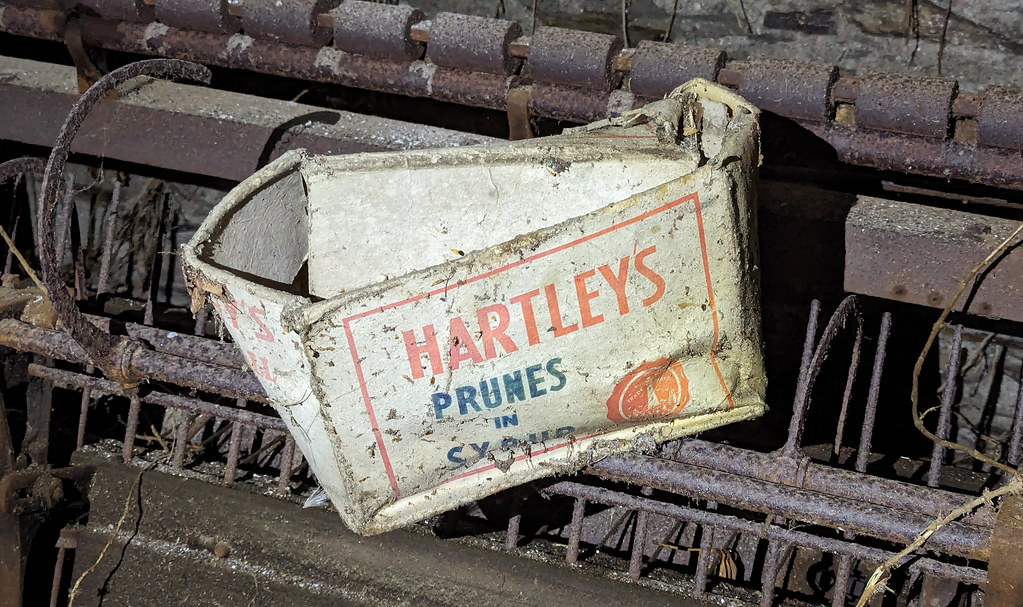

And prune lovers:

A newer looking machine:

Old wheels for the drive shafts:

And a larger one that’s still attached:

Ceulan Woollen Mill is located in the village of Tal-y-bont in Ceredigion, located halfway between Aberystwyth and Machynlleth. The village stands on two rivers, the Afon Ceulan and Afon Leri. These fast-flowing rivers attracted a number of mills to the village. Three were built along the Leri while a single mill was built on the Afon Ceulan. It was built in 1847 by the Morris family and was working by 1860. It produced cloth and flannel mainly for shirts for farmers and coal miners throughout mid and south Wales. The building consisted of two storeys and an attic and was constructed of split local rubble in a lime mortar, under a slate roof. Due to the success of the mill, it was extended in 1880 and a 7.7m diameter breast-shot waterwheel added against the mill’s southwest gable.

The waterwheel powered the mill machinery and in around 1920 it also drove an electric generator. In 1923 a double Pelton wheel turbine was installed by Edwards of Llanuwchllyn, on the north-east gable in order to drive both the mill machinery and an electric generator. During the Second World War, production and profits suffered. Thinks improved post-1945 but the mill struggled to complete with the bigger mills and their large modern machinery. It struggled on for around a decade before the mill ceased working around 1955, despite turning part of the mill into a shop to sell the directly to the public. It was then eventually abandoned in 1962. Sometime after the owner attempted to pass the mill to the National Trust for preservation. A lack of funding to restore and repair the mill meant the NT were unable to take the mill on.

2. The Explore

So the main reason for driving the 15 of so miles south of where we were staying to Tal-y-bont was to see Leri mill with is colourful yarns. This proved too much of a challenge sadly. The mill lies over the River Leri, reached either across the fallen tree over the river or via a wade. With the biblical rainfall the day before the river was swollen and fast flowing so neither option appealed. I even tried approach from the west but the mill lies at the bottom of a steep bank. So plan B was to check out Ceulan Mill. Entry was pretty straight forward and the main challenge was how to best capture this packed-to-the-gills three storey mill in extremely poor light. Hopefully I just about managed that. After a good hour or so it was time to head back to the car and back up to Mach.

3. The Pictures

All phone pics, using a combination of natural light and my torches.

And we’re in:

It’s pretty overwhelming:

The amount of machinery on the ground floor is ridiculous:

Not too sure what these are:

Cool old Player’s box:

Some old documentation:

And very old electrics:

What a load of old bobbins:

These cog wheels are fantastic:

There’s even an old butter churn:

More bobbins!

In black and white:

One for the comrades!

And prune lovers:

A newer looking machine:

Old wheels for the drive shafts:

And a larger one that’s still attached: